Window Options

Hörmann Window Options

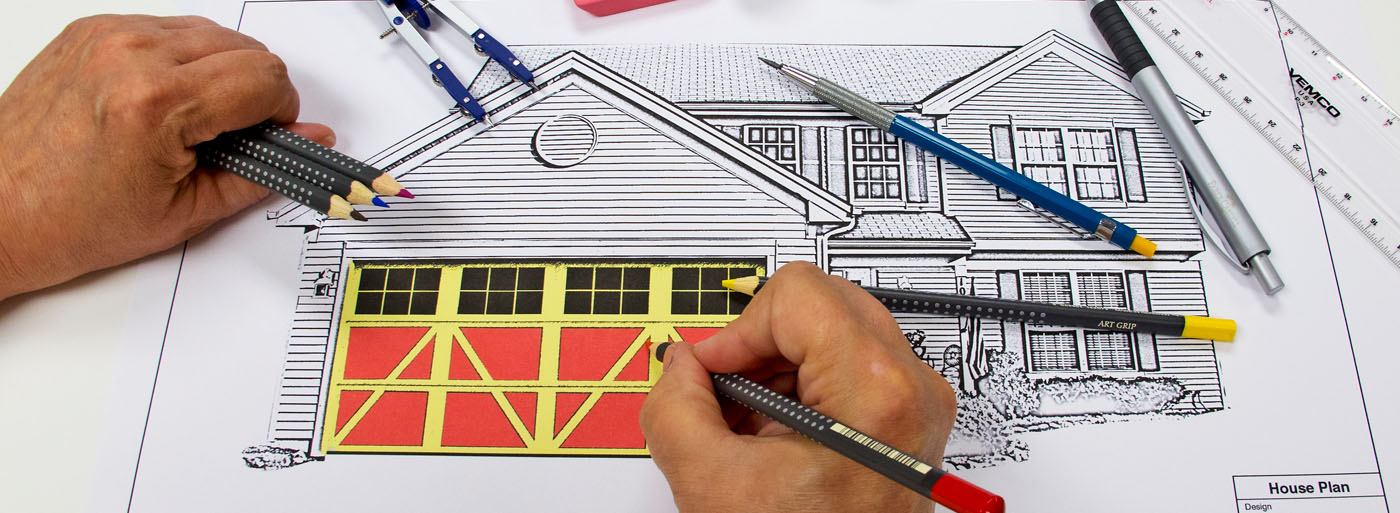

Rejuvenate the look of your home instantly, the right way, with the Hörmann exclusive Mix ‘N Match garage door window system. In just minutes you can give your home a whole new look, enhance its curb appeal and even increase its resale value.

For Traditional & Country Designs Hörmann window insert frames are recessed in to the panel surface to give your door a cleaner look and free from any obstructions. Inside window frames are injection molded and assembled using screws for convenience in replacing glass pane and clean look. Hörmann’s robust solid piece injection molded windows inserts offer superior rigidity and more durable compared to other welded frames. Hörmann snap-in window inserts are offered in all 9 standard colors and 4 wood tone colors.

Semi-Custom Colors

The Galaxy Paint System offers 28 pre-selected semi-custom colors to match the colors of house coverings, trims and soffit hues of most modern homes.

| Almond | Desert Tan | Sandstone | Teratone* |

| Brown* | Deep Crimson* | Hunter Green* | Industrial Grey |

| Pebble Grey (RAL 7032) | Brown Beige (RAL 1011) | Cement Grey (RAL 7033) | Agate Grey (RAL 7038) |

| Beige (RAL 1001) | Copper Brown (RAL8004) | Moss Grey (RAL 7003) | Slate Grey* (RAL 7015) |

| Pale Brown (RAL 8025) | Carmine Red (RAL 3002) | Reed Green (RAL 6013) | Pigeon Blue (RAL 5014) |

| Mahogany Brown* (RAL 8016) | Wine Red* (RAL 3005) | Reseda Green (RAL 6011) | Signal Blue* (RAL5005) |

| Jet Black* (RAL 9005) | Chestnut Brown* (RAL 8015) | Leaf Green* (RAL 6002) | Sapphire Blue* (RAL 5003) |

Paint System Features

- Galaxy Paint System is available on the following door series: Orion 3200, Phoenix 5200, Tucana 5250 and Solaris 7200.

- Choose from any of the 28 semi-custom colors or submit a sample of your desired color to your Hörmann Dealer for a genuine custom finish.

- Galaxy Paint System is a factory applied top coat sprayed over the pre-painted steel. This is an added layer of protection and does not affect the Limited Lifetime warranty of the sections, however, the top coat itself will be covered for a period of one (1) year against crazing, blistering, peeling, chalking, or fading as defined in the Galaxy Paint System warranty.

- The paint system utilizes a high quality catalyzed acrylic urethane that is far superior to any exterior paints that are typically used by a painting contractor.

- To prevent webbing or missed spots, all components are painted separately, cured and then assembled prior to packaging.

- Considering the cost of rollers, brushes, cleaners, drop cloths and time spent while painting the door yourself or hiring an expensive painting contractor, the Galaxy Paint System provides a more cost effective solution and will retain the superior finish much longer.

Custom Colors

Your home is as unique as you and your family so why settle with a color selected from a handful of choices? Expresss yourself with the Galaxy Paint System.

The Galaxy Paint System utilizes the latest in today's painting technology to match any submitted color within the tightest of tolerances. With the Galaxy Paint System, you will not only be confident that you have purchased the highest quality and safest garage door for your home but one that will match the color of its exterior with a factory finish that will last.

Hörmann Advantages

- Unlimited color matching capability for a perfect color match

- Paint that far exceeds the quality of anything available for on-site finishing

- Factory painted prior to final assembly

Paint Performance

The following tests were conducted on panels spray coated with White Satin Polyurethane 1.25 - 1.5mils dry film thickness (DFT), and aged for nine days at 77°F (25ºC) at 50% RH. Tests meeting ASTM Standards are noted.

- Salt Spray

ASTM B117, 2000hrs. unscribed area. No corrosion. - 100% Relative Humidity

ASTM D2247, 1000 hrs. No blisters. - Ultraviolet Accelerated Weathering

ASTM G53, UVB-340nm lamps. Test cycle: 8 hrs. UV/4hrs CON 2500 hrs, 94% of original gloss retained. UVB313nm lamps. Test cycle: same, 2500 hrs, 82% retention. Color change less than 1.0 DE. - Florida Environment Exposure - 45º Facing South

3 yrs exposure: 88% of original gloss. - Abrasion Resistance - Taber Abraser

ASTM D4060. CS-17 wheel, 1000g load: 1000 cycles less than 90mg loss - Impact Resistance

ASTM 2794. Direct and Indirect impact: 160 inch-pounds. - Pencil Hardness

ASTM D3363: greater than 2H - Cross-hatch Tape Adhesion

ASTM D3359 Method B, 5B (100% adhesion). - Solvent Resistance

Panels aged at room temperature for two weeks. No film degradation in 100 double rubs with the following solvents: Lacquer Thinner, Acetone, Xylene, MEK, Gasoline. - Oil and Stain Resistance

ASTM D1308, Panels immersed in lubricating oil for 72 hrs at 100ºC - 105°C and 200 hrs at room temperature: No effect. Panel spot tested, covered watch glass for 24 hrs with food coloring. Wiped clean with soap and water. No staining.

Download Information Brochure

Download PDF

(0.4 MB)